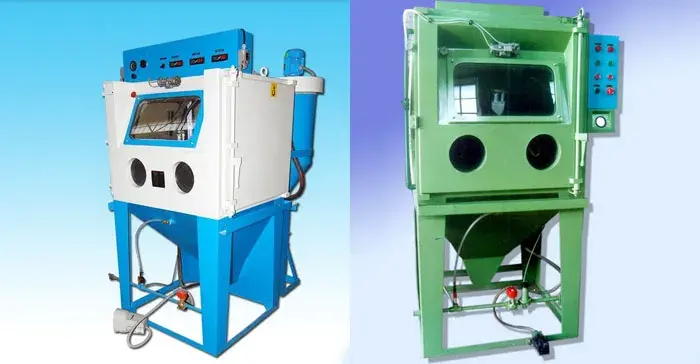

- Precision Cleaning: Our wet blast cabinets utilize a water-abrasive slurry to achieve precise cleaning and surface preparation, ideal for sensitive materials and components.

- Versatility: Suitable for a variety of blasting media, our cabinets accommodate different materials and applications, ensuring flexibility in operations.

- Efficiency: Engineered for efficient performance, our wet blast cabinets enhance productivity while maintaining high standards of cleanliness and quality.

- Advanced Features: Equipped with advanced features such as adjustable blasting pressure and flow controls, our cabinets offer customizable blasting parameters for optimal results.

- User-Friendly Design: Designed with ergonomic controls and easy-access features, our cabinets promote ease of use and operator comfort, minimizing downtime.

- Durable Construction: Built with durable materials, our cabinets ensure longevity and reliability, even in demanding industrial environments.

- Comprehensive Support: We provide comprehensive after-sales services including installation, training, maintenance, and technical support to maximize machine uptime and efficiency.

- Safety: Our wet blast cabinets incorporate advanced safety measures to protect operators and maintain a secure working environment.

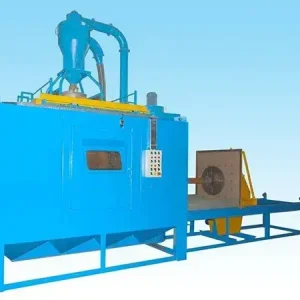

Our wet blast cabinets are designed to deliver precision cleaning and surface preparation, making them ideal for a wide range of industrial applications in Ahmedabad. They utilize a water-abrasive slurry to achieve meticulous cleaning of sensitive materials and components. Versatile in accommodating various blasting media, our cabinets provide flexibility to suit diverse material types and operational needs.

Engineered for efficiency, they enhance productivity while ensuring high standards of cleanliness and quality. Advanced features such as adjustable blasting parameters and user-friendly controls optimize operational performance and minimize downtime. Built with robust materials, our cabinets offer durability and reliability for consistent performance in challenging industrial environments. With comprehensive after-sales support, including installation, training, maintenance, and technical assistance, we ensure our wet blast cabinets operate at peak efficiency. Safety is paramount, and our cabinets are equipped with advanced safety features to safeguard operators and maintain workplace security.

Why Choose Aerowheel Surface Finishing for Wet Blast Cabinets in Ahmedabad?

- Expertise and Experience: With years of experience in manufacturing wet blast cabinets in Ahmedabad, we possess the expertise to deliver superior solutions tailored to specific industrial needs.

- Innovation: We are committed to innovation, integrating advanced technology to enhance the performance and efficiency of our wet blast cabinets.

- Quality Assurance: Rigorous quality control measures ensure that our cabinets meet the highest standards of performance, durability, and reliability.

- Customer-Centric Approach: We prioritize customer satisfaction, offering personalized solutions and exceptional service to meet individual requirements.

- Global Reach: Beyond Ahmedabad, we serve diverse industries globally, providing top-quality wet blast cabinets designed for precision and efficiency.

Aerowheel Surface Finishing stands out as a trusted manufacturer of wet blast cabinets in Ahmedabad, delivering advanced solutions for precision cleaning and surface preparation. Contact us today to explore how our wet blast cabinets can optimize your industrial processes and meet your specific operational needs effectively.

Reviews

There are no reviews yet.