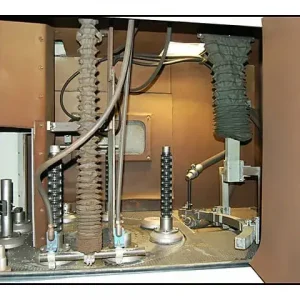

How Abrasive Blasting Cabinets Work

The operation of abrasive blasting cabinets varies in intensity based on desired outcomes, generally involving:

- Mixing abrasive materials like sand with air inside a pressure vessel.

- Directing the pressurized mixture through a handheld nozzle towards the targeted surface.

- Utilizing different nozzle shapes, sizes, and materials (such as boron carbide) for optimal blasting results.

Benefits of Choosing Abrasive Blasting Cabinets Manufacturers in Ahmedabad

Aerowheel Surface Finishing, as leading abrasive blasting cabinets manufacturers in Ahmedabad, offers significant advantages over traditional cleaning methods:

- Universal Applicability: Our cabinets handle various tasks including cleaning, derusting, descaling, hardening, deburring, roughening, compacting, and polishing.

- Versatility: They support all types of blasting media, allowing selection based on specific needs.

- Convenience: Ready-to-operate cabinets with all necessary connections ensure immediate use.

- Safety: We prioritize safety by using high-quality materials and adhering to stringent standards.

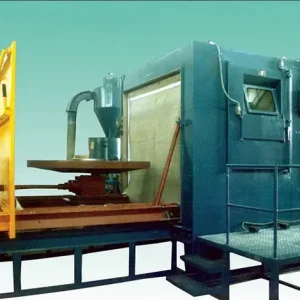

Types of Abrasive Blasting Cabinets Offered by Aerowheel Surface Finishing in Ahmedabad

We provide a diverse range of abrasive blasting cabinets to meet unique requirements:

- Suction/Vacuum Blast Cabinets: Cost-effective and advanced, ideal for light abrasives and corrosion cleaning.

- Pressure Blast Cabinets: Operate on direct pressure principles, suitable for heavy abrasives and tough cleaning tasks.

- Wet Blast Cabinets: Use a water-abrasive slurry for delicate cleaning, perfect where dust generation is a concern.

- Rotary Indexing Machines: Designed for high-volume production, featuring a rotating turntable for efficient blasting.

- Roll Etching Machines: Automate etching and roughening tasks on rolling mill rolls with direct pressure operation.

- Tyre Mould Cleaning Machines: Specifically designed for cleaning tyre moulds, equipped with advanced features for optimal performance.

Why Choose Aerowheel Surface Finishing in Ahmedabad for Your Abrasive Blasting Cabinet Needs?

At Aerowheel Surface Finishing in Ahmedabad, we are dedicated to providing top-quality abrasive blasting cabinets and exceptional service. We offer:

- A wide range of cabinet types and sizes tailored to specific needs.

- Robust, reliable cabinets crafted with superior craftsmanship.

- Competitive pricing and flexible financing options.

- Expert technical support and customer service.

- Turnkey project execution for a seamless experience.

Explore Our Turnkey Blasting Cabinet Projects

Visit our project page to see how our abrasive blasting cabinets are utilized across various industries. Gain insights into potential applications and choose the right cabinet for your specific requirements.

Contact Us Today for a Free Consultation

Our experienced team is ready to assist you in selecting the ideal abrasive blasting cabinet for your needs. Contact us today in Ahmedabad for a free consultation and discuss your specific requirements.

Pradeep Saran –

Hey fellow surface enthusiasts! I recently got my hands on an Abrasive Blasting Cabinet for AeroWheel Surface Finishing, and let me tell you, it’s been a game-changer for my projects here in Jodhpur city. This nifty piece of machinery has not only made the job easier but also upped the quality of my surface finishes.

First off, let’s talk about the price. We all know how crucial it is to find a sweet spot between quality and affordability. I did my fair share of research, and I must say, the price of the Abrasive Blasting Cabinet was quite reasonable. I managed to snag a great deal, and considering the efficiency it brings to the table, it’s definitely worth the investment.

Now, onto the manufacturer. I opted for a trusted manufacturer in India, and I couldn’t be happier with my choice. The build quality is top-notch, and it’s evident that they’ve put a lot of thought into designing a product that can withstand the demands of AeroWheel Surface Finishing. The durability alone is enough to convince me that I made the right call.

Living in Jodhpur, where the dust and sand can be a real challenge for surface finishing, this abrasive blasting cabinet has proven to be a reliable ally. The enclosed design ensures that the abrasive material stays where it’s supposed to, making the workspace much cleaner and safer. No more worrying about contaminants ruining my hard work!

One standout feature is the efficient blasting mechanism. The cabinet provides a controlled environment for the blasting process, allowing me to achieve a consistent and precise finish on AeroWheels. The visibility inside the cabinet is excellent, thanks to well-placed lighting, making it easy to monitor the progress of the blasting.

Cleanup is a breeze too. The cabinet comes equipped with a dust collector that efficiently sucks up the debris, keeping the workshop tidy. This not only saves time but also makes the entire process more eco-friendly by minimizing waste.

All in all, I’m thoroughly impressed with the Abrasive Blasting Cabinet for AeroWheel Surface Finishing. It’s a reliable, efficient, and reasonably priced solution that has elevated the quality of my work here in Jodhpur. If you’re serious about achieving top-notch surface finishes, this is definitely a tool worth considering. Happy blasting, fellow craftsmen!